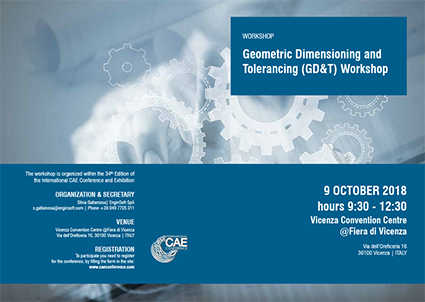

9 OCtOBER 2018 HOURS 9:30 - 12:30 | WORKSHOP

Geometric Dimensioning and Tolerancing (GD&T) Workshop

8:30 - 9:30 Registration

09.30 – 09.50 F. Weidenhiller, VSA

Dimensional Management Introduction: engineering methodology combined with computer-simulation tools used to improve quality and reduce cost. The objective is to create a design and process that "absorbs" as much variation as possible without affecting the function of the product

09.50 – 10.10 G. Concheri - R. Meneghello, University of Padova

GD&T: ISO & ASME standards Current regulatory framework and future trends. Main reasons for which your company should be aware of these standards (and why it is not!)

10.10 – 10.30 F. Leali, University of Modena and Reggio Emilia

GD&T: basic concepts Role of the standards in design intent communication: functional requirements, basic concepts in geometric deviations, datum reference frames, geometric & dimensional tolerances

10.30 – 10.50 E. Boesso, EnginSoft

Model Based Definition– Model Based Enterprise (MBD-MBE) CAD files used to exchange PMI (Product Manufacturing Information) data. Opportunities of data digitization and data standardization along the product development process

Coffee break 10.50 - 11.20

11.20 – 11.40 S. Cascella, Leonardo Company

Tolerance Analysis & Synthesis (Optimization) Effect of the propagation of parts-related tolerances to the final product: calculation of 3D tolerances chains, preliminary (virtual) design validation and smart corrective actions + Optimization of the tolerance widths based on the functional requirements and production-related costs

11.40 – 12.00 J. Stoddard, SIGMETRIX

Faster-Better-Cheaper products Benefits and Impacts adopting Tolerance Chain analysis in different industrial sectors

12.00 – 12.20 G. Graziosi, GOM

Dimensional Controls Leverage MDB in dimensional controls: automation of the inspection plans, conformity of the measures to the functional requirements, statistical process control and virtual evaluation of non-compliances

Ensuring the reliability of hi-tech products can only be achieved by design engineering processes that properly consider the products’ geometric and dimensional deviations. This level of detail is vital today to achieve the competitive advantage resulting from reduced re-design cycles, cost-savings at the prototype stage, minimization of non-conformities, more cost-effective manufacturing processes, and reduced time-to-market.

Truly robust design is engineered through the integrated management of tolerances. This involves tolerance propagation analysis along with a geometric and dimensional description that complies with the latest international standards (ISO-GPS and ASME/GD&T). These enable the creation of complete sets of tolerance parameters that can be uniformly interpreted, a key aspect in data digitalization to leverage process automation. Engineers can use these tools during the design phase to identify the tolerances that will have the greatest impact on the product’s functional requirements. This information can be used to make the essential corrections while increasing the other tolerances to accommodate Production’s requirement to limit costs.

This workshop will demonstrate how companies can leverage state-of-the-art GD&T methods and instruments to create more robust hi-tech products while containing production costs.

It will present the best methods and instruments available to identify the ideal compromise between the Designer’s demands to meet the end-product requirements, and Manufacturing’s need to rapidly and cost-effectively produce and assemble the components.

VENUE

Vicenza Convention Centre @Fiera di Vicenza

Via dell’Oreficeria 16 |

36100 Vicenza | ITALY

DATE

9 OCTOBER 2018 | HOURS 9:30

REGISTRATION

The workshop is organized within the 34th Edition of the International CAE Conference and Exhibition.

To participate you need to register for the conference.

ORGANIZATION & SECRETARY

Silvia Galtarossa |

EnginSoft SpA

s.galtarossa@enginsoft.com | Phone +39 049 7705 311